Search

Search

Search

Search

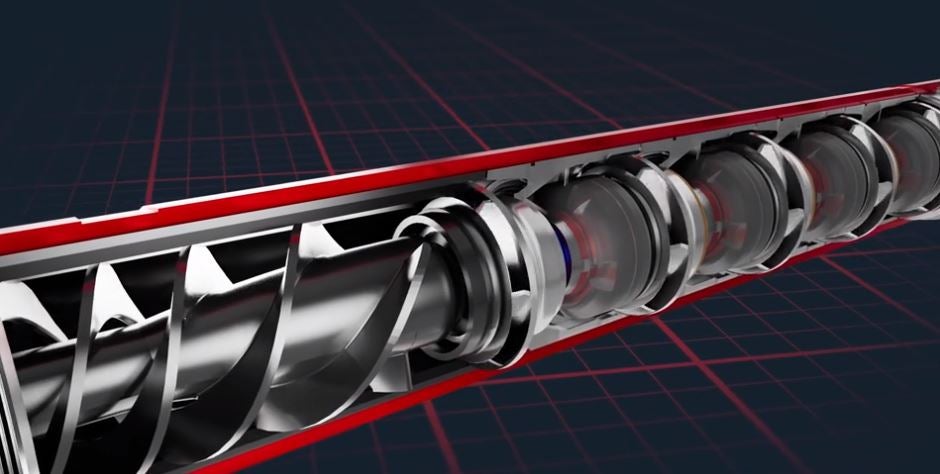

The Hydro-Helical® gas separator sets a new industry standard for flow rate, performance, and reliability and is available in 400 and 538 series.

Helping maximize value by increasing oil production in conventional and unconventional wells with very high gas concentration.

03.06

Case Study: Oklahoma

Hydro-Helical® gas separator and SandRight® Solids Fallback Preventer combined with monitoring and remote interventions to further optimize production.

Read Case StudySeparation efficiency

Flow rate versus conventional separators

Flow rate in integral tandem configuration

CASE STUDY: THE BAKKEN

Operator boosts oil well production with new gas separation technology

See Case Study